Expert Advice: Top Maintenance Tips for Long-lasting Generator Performance

Regular Inspection and Cleaning

One of the most crucial aspects of maintaining a generator is conducting regular inspections and cleaning. Over time, dust, debris, and other contaminants can accumulate, affecting the generator's efficiency. Inspect your generator every few months for any visible signs of wear and tear or potential issues. Make sure to clean the air filters and other accessible parts to ensure optimal performance.

Keeping the generator clean not only boosts its performance but also prolongs its lifespan. Use a soft brush or compressed air to remove any dirt from the surface. If you notice any corrosion on metal parts, address it immediately to prevent further damage.

Oil and Filter Changes

Just like a vehicle engine, a generator's engine requires regular oil changes to function efficiently. Check the oil level before starting the generator and change the oil according to the manufacturer's recommendations. This usually involves changing the oil every 50 to 100 hours of operation.

Additionally, replace the oil filter when you change the oil to ensure that the oil remains clean and free of contaminants. A clean filter helps maintain the generator's performance and protects its engine components from unnecessary wear.

Battery Maintenance

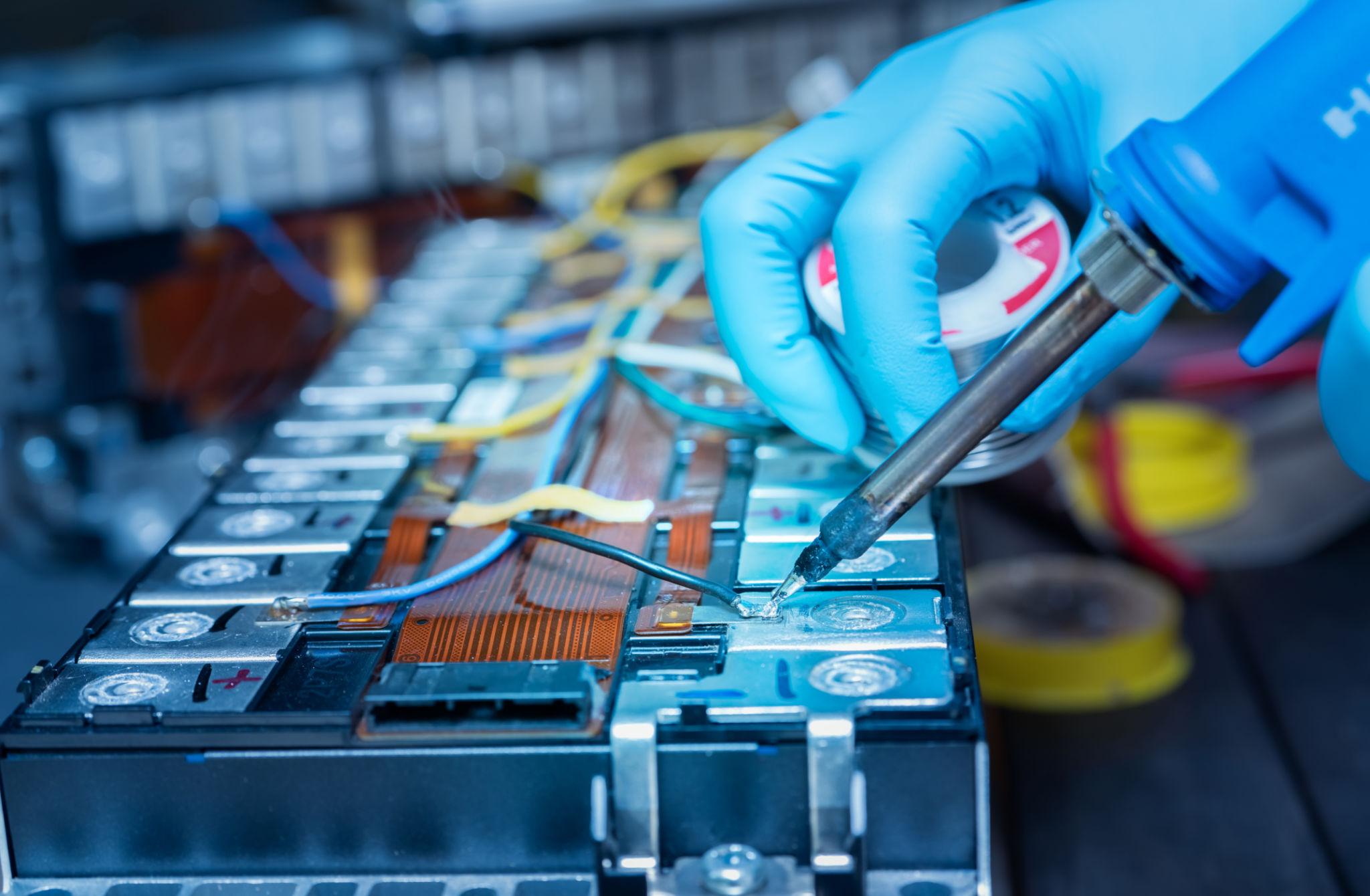

The battery is a critical component of your generator's electrical system. Without a functioning battery, your generator may fail to start when you need it most. Regularly check the battery terminals for any corrosion and clean them with a baking soda solution if necessary.

Ensure that the battery is fully charged and conduct load tests periodically to assess its condition. Replace the battery if you notice any signs of weakness, such as a slow start-up or dimming lights.

Fuel System Care

Taking care of your generator's fuel system is essential for its long-term performance. Always use fresh fuel and avoid mixing different types of fuel. Stale fuel can lead to clogs in the fuel system, causing poor performance or failure to start.

If your generator uses diesel or gasoline, consider using a stabilizer additive to keep the fuel fresh during periods of inactivity. Additionally, regularly inspect fuel lines and tanks for leaks or damage and address any issues promptly.

Cooling System Check

A generator's cooling system prevents it from overheating during operation. Ensure that the coolant levels are adequate before running your generator. If you notice any leaks or drops in coolant levels, investigate immediately to prevent potential damage.

Regularly inspect the radiator and hoses for any signs of wear or damage. Clean the radiator fins using compressed air to remove dust or debris that might obstruct airflow.

Test Runs and Load Testing

Conducting regular test runs and load testing is imperative for maintaining your generator’s reliability. A monthly test run helps identify potential issues before they become significant problems. During these test runs, simulate a power outage by disconnecting from main power and allowing the generator to take over.

Load testing ensures that your generator can handle its expected operational load effectively. It provides insight into how the generator responds under stress, helping you identify any weaknesses or required maintenance adjustments.

Professional Servicing

While regular DIY maintenance is essential, don't underestimate the value of professional servicing. Schedule an annual inspection with a qualified technician who can perform a comprehensive evaluation of your generator. They can identify problems that might not be apparent during routine checks and provide expert solutions.

Professional servicing often includes advanced diagnostics, component replacements, and adjustments that ensure your generator runs smoothly and efficiently throughout its service life.